The Importance of a Proper Installation

Omni Containment Systems designs products that enable our clients to exceed their fats, oils, and grease containment needs with cost effective, environmentally responsible solutions. We have partnered with over 900 distribution and service partners to offer the most comprehensive line of NFPA 96 compliant grease containment products in the world. At Omni Containment Systems, we strive to make the best product, however, it isn’t much help if the installer hasn’t received the right training or the right product has not been applied.

That is why we stress the importance of choosing the correct system and proper installation with all of our products. Our products have been tried and tested on over 20,000 restaurants and food processing facilities around the world. If the containment system you have purchased is not performing correctly, chances are the installed product was set up for failure. Omni Containment is unlike other companies who offer one solution for many different problems. At Omni, we understand that there are many factors to consider when choosing the right grease containment system to protect your rooftop. That is why we offer several different off-the-roof grease containment systems to choose from.

When you are choosing a grease containment system for your rooftop you need to consider the type of fan and the grease output. Exhaust fan volume is determined by the input of the cooking line, this in turn indicates which system you need to protect your rooftop. For instance, you obviously could not use a Sidekick on an industrial-type exhaust fan. Does the exhaust fan need a one-sided grease protection system or a four-sided one? Is the grease exhaust fan volume low, moderate, or high? Omni’s commitment has always been to provide products that solve problems. If you run into a problem or need advice on a rooftop situation, remember we are here to help.

on an industrial-type exhaust fan. Does the exhaust fan need a one-sided grease protection system or a four-sided one? Is the grease exhaust fan volume low, moderate, or high? Omni’s commitment has always been to provide products that solve problems. If you run into a problem or need advice on a rooftop situation, remember we are here to help.

Once you have chosen the right system to work with your grease containment needs, it is crucial to have the Omni Containment Systems’ product installed correctly. As we stated before, even if you have the best product, it can fail if it has not been accurately installed. Installation instructions are included with every product we ship, and we have step-by-step installation videos for most of our products on our website. Although we strive to provide products that are also easy to install and service we do run into instances where the product was not installed correctly.

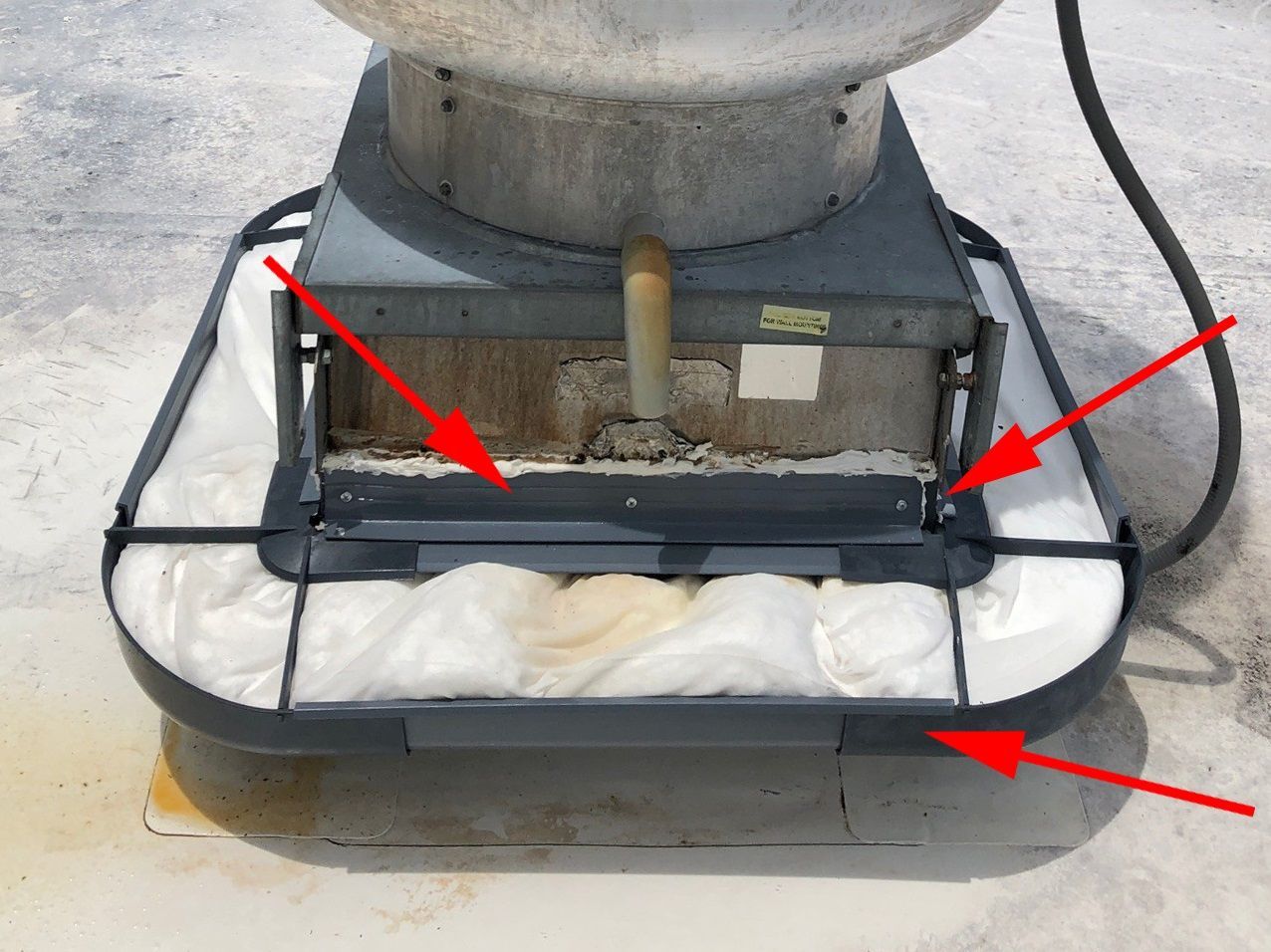

This picture is a perfect example of an improperly installed Grease Gutter® containment system. Due to the improper installation, it set this brand-new system up for failure. The corners of the gutter were not installed flush with the trough, this disrupted the engineered flow of the Grease Gutter®. Let’s analyze what happened here. To begin, there are only three screws; the gutter is not securely mounted onto the curb of the fan. On a properly installed system you would see eight screws equally spaced along the curb of the fan, universally spread on each side. This secures the Grease Gutter® troughs. Secondly, the corners should be flush with the secured trough lengths with screws securing it in place, along with caulking placed in all the seams. Additionally, the holes on the spout side should be sealed with caulking and only the holes on the backside remain open for water-flow. When all these measures are applied, the corners will sit flush with the trough and not sag as seen.

If the corners are not flush it inhibits the flow of the Grease Gutter®. The Grease Gutter® is designed to capture the grease as the grease and water flow around to the backside of the system. This allows the Fill-More Grease Boom the ability to capture up to 5 gallons of ventilator grease discharge. The boom only absorbs the grease discharge not precipitation. This filtration system is second to none. When the framework is installed properly it allows the Fill-More Grease Boom

the ability to capture up to 5 gallons of ventilator grease discharge. The boom only absorbs the grease discharge not precipitation. This filtration system is second to none. When the framework is installed properly it allows the Fill-More Grease Boom to function as designed.

to function as designed.

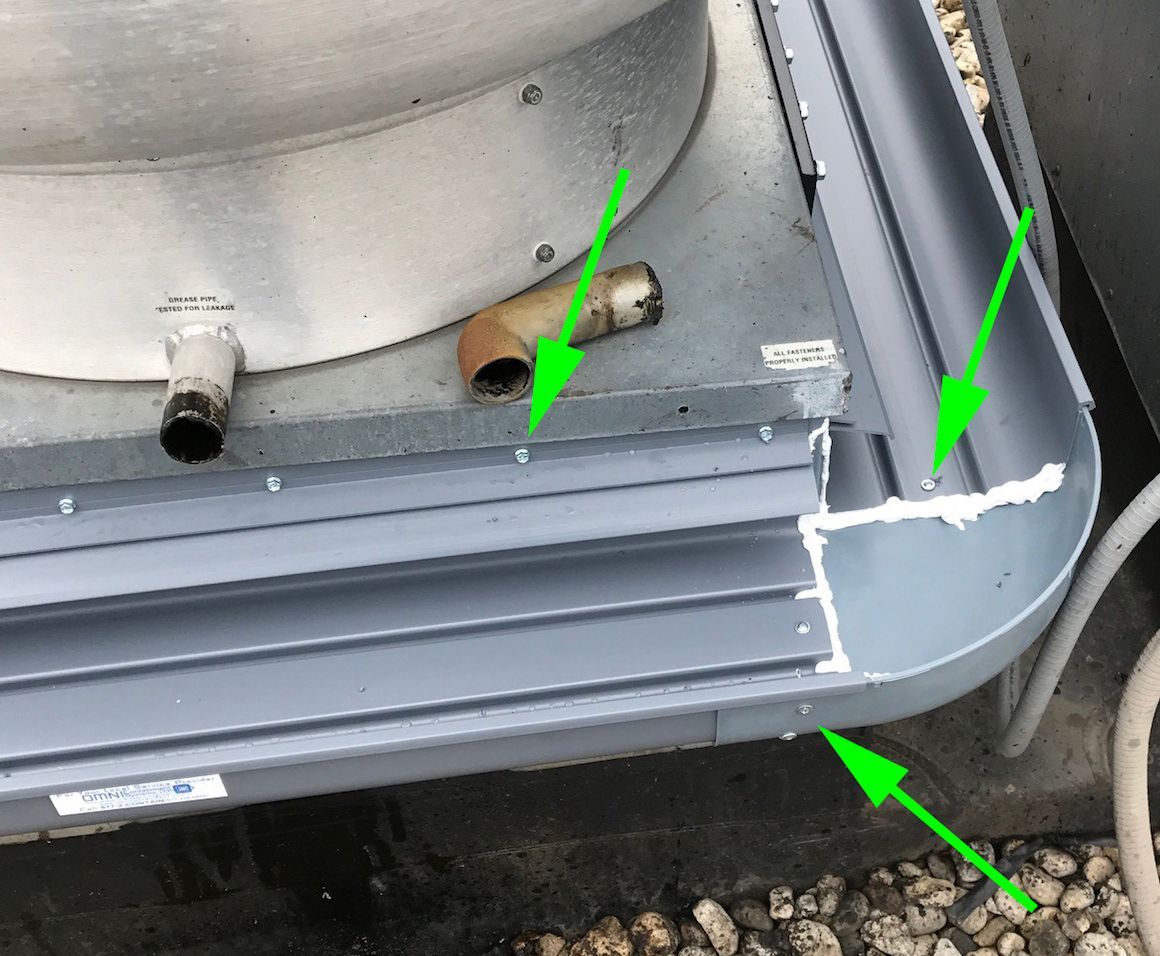

A properly installed Grease Gutter® containment system will sit flush and evenly as seen in these pictures. You will also notice that the gutter flashing is properly secured with screws universally spread on each side. The corners are perfectly screwed into alignment along the secured trough lengths, caulking has been placed on all the seams, and the two front holes on the spout side have been sealed with caulking.

When you make the decision to invest in the right containment system it is equally important to allow the same care with the installation process. As in the above instance, they have voided their warranty due to an improper installation. If you are on-site doing an installation and run into a problem, you can call our office at 847-468-1772. Our trained staff have been on rooftops, have first-hand experience installing Omni products, and have the expertise to direct and walk you through the necessary steps for a successful installation. If you feel at any time that you do not have the expertise, reach out to your sales representative who can arrange an installation with one of our 900 service partners. We definitely have one in your area!

Omni Containment Systems strives to protect as many rooftops from grease as possible. Our products are proudly made here in the USA and we back them up with a warranty. However, if you abuse, misuse, or fail to maintain the product in accordance with the manufacturer’s standard, it will void the warranty. It pays to slow down, ask questions, and above all, to install correctly.

Share This Blog Post!