Choosing the Right Equipment for Business Growth

For businesses specializing in kitchen exhaust cleaning, the decision to upgrade or invest in new tools is crucial for progress. Whether you want to expand services, handle more complex systems, or boost efficiency, having the right equipment is key to moving forward instead of remaining stagnant.

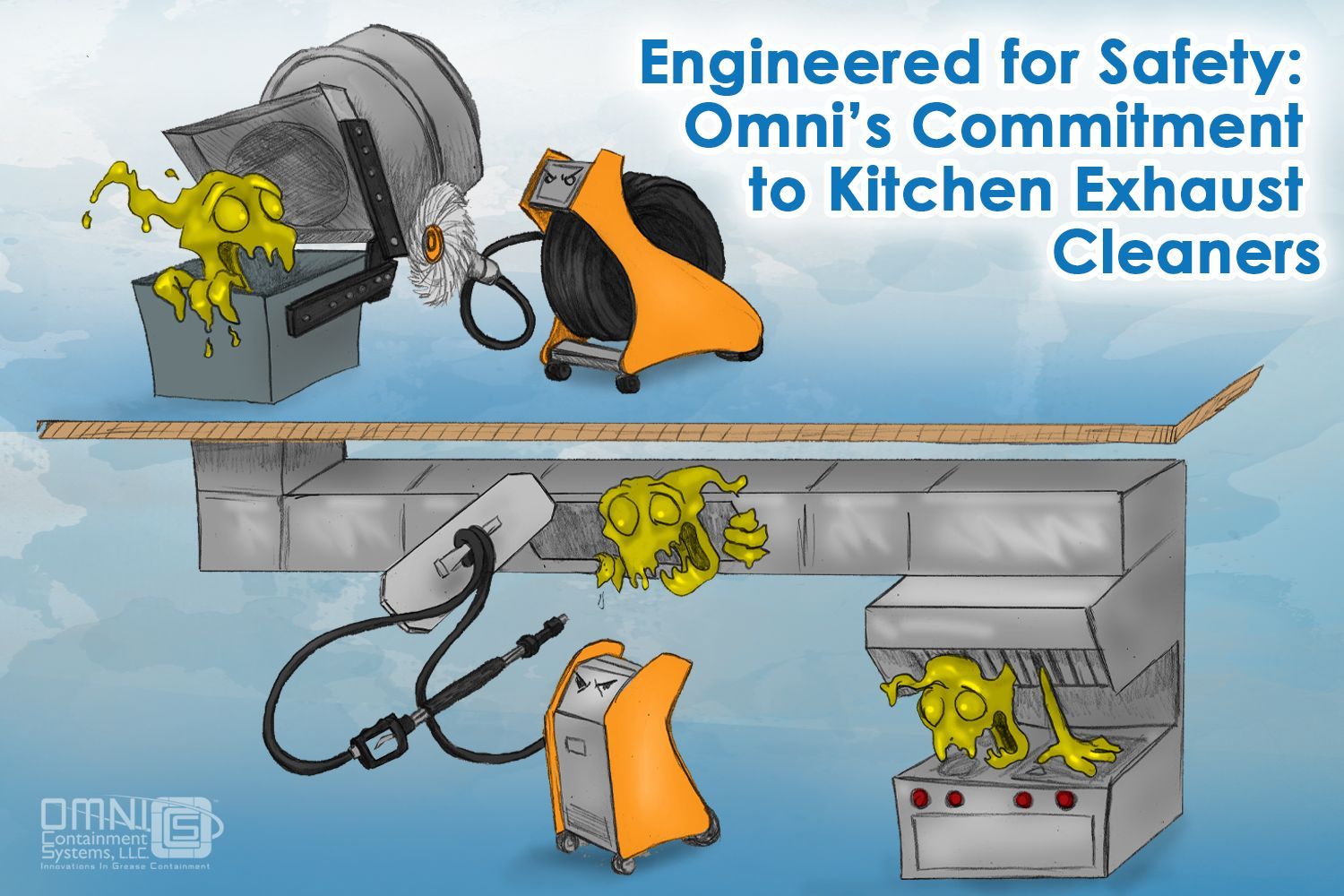

At Omni Containment Systems we are experienced in this process and take pride in offering cutting-edge solutions like the Tegras and Tecai systems by Teinnova. These systems are designed to assist kitchen exhaust cleaning professionals in safely and effectively handling even the most challenging tasks.

Our expert team is dedicated to helping you navigate the complexities of equipment selection, ensuring that you choose the right solutions tailored to your specific needs. With our innovative products, you can enhance efficiency and drive success in your operations.

The Importance of Equipment in the Current Business Environment

The restaurant landscape is rapidly changing, with trends such as open kitchens, solid-fuel cooking, intricate ductwork, and high-capacity grease systems becoming more prevalent. As a kitchen exhaust cleaning professional, you may encounter systems with extensive lateral ductwork that require tools such as ladders, chemicals, and significant labor.

Without the right equipment, your team may be ill-prepared, overwhelmed, and less competitive.

5 Tips for Making Equipment Purchases

1. Assess Your Situation and Set Clear Goals

Start by evaluating your current challenges:

- Are complex tasks causing difficulties?

- Do you need to boost productivity?

- Are competitors providing better service or faster turnaround times?

Addressing these questions helps ensure that your purchase aligns with your growth objectives and your client's needs.

2. Plan Before Buying

Identify what is working well and what needs improvement in your business. Map out workflows, identify pain points, and determine where new equipment can enhance outcomes. This approach ensures that your investments are strategic rather than impulsive.

3. Consult a Trusted Advisor

Before making a purchase, seek advice from a reputable supplier like Omni Containment Systems. We can help assess your needs, offer a cost-benefit analysis, and guide you towards a purchase that fits your strategy. You don't have to navigate this process alone.

4. Choose Reliable Suppliers

Thoroughly research equipment suppliers. Consider factors like quality, training support, and post-sales service in addition to price. When you choose Omni, you benefit from hands-on training and a knowledgeable team.

5. Account for Training Needs

Introducing new equipment may cause temporary slowdowns if your team lacks proper training. Allocate time for staff training and opt for a supplier that includes this service. With Tegras and Tecai, Omni provides product training for seamless onboarding.

Benefits of Tegras and Tecai Systems

Embrace Innovation for a Competitive Edge

Teinnova's commitment to research and development ensures that Tegras and Tecai systems incorporate the latest advancements in kitchen exhaust cleaning technology. These systems offer significant improvements in performance and user-friendliness.

Boost Efficiency

Tegras equipment, with features like active foam, mechanical brushes, and compressed air, automates a large part of the cleaning process, saving time for each task. This solution is ideal for meeting deadlines and handling hard-to-reach systems.

Support Technician Well-Being

Outdated or faulty equipment can lower morale. High-quality, reliable tools increase productivity, reduce frustration, and help retain skilled technicians. Tecai systems prioritize technician comfort and effectiveness.

Facilitate Growth and Progress

Upgraded equipment allows you to onboard more clients, introduce new services, and tackle challenging projects. Many Omni customers have expanded their teams and revenue after adopting the Tegras concept.

Prioritize Safety

Safety is paramount. Teinnova's equipment includes features like the Comegras jug container, which is the perfect size and weight to make it very manageable and portable, reducing chemical handling and operator risks. Tegras and Tecai undergo rigorous safety testing and are designed for daily field use.

Conclusion: Your Investment in Success

When you invest in the right equipment, you are investing in your team, reputation, and future success.

Let Omni Containment Systems be your partner on this journey. From assessment to product selection, training, and support, we are here to help you maximize the benefits of every investment.

Ready to enhance your operations?

Contact us today to explore Tegras and Tecai equipment and enjoy the peace of mind that comes with working smarter, not harder.

Share This Blog Post!