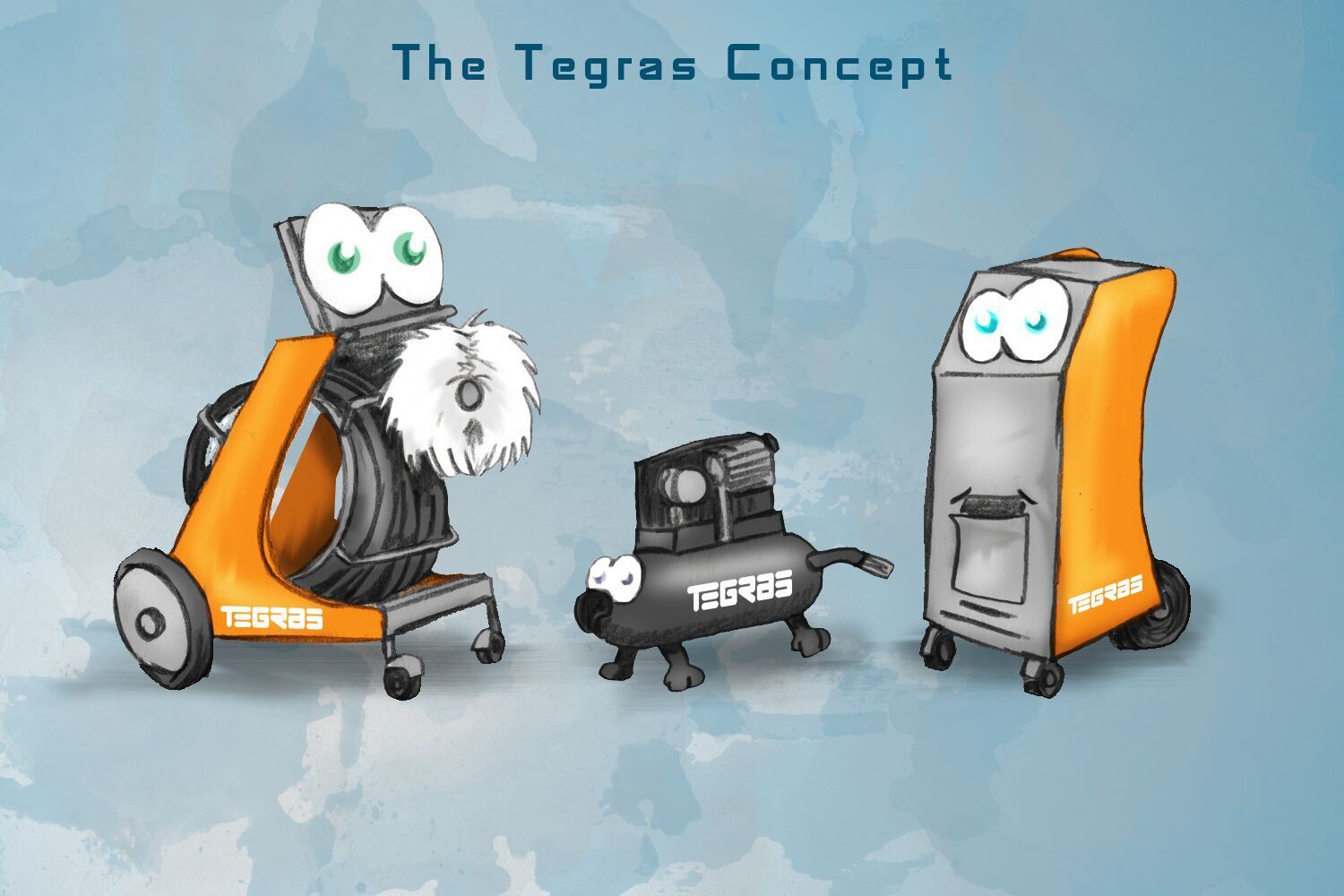

The Tegras Concept

Omni Containment Systems partnered with Teinnova , a Spanish manufacturing company, in 2017; this makes us the sole North American distributor of their Tegras hood cleaning system. Our goal here at Omni is provide products that will help keep restaurants and people safe, are easy-to-use, and efficient. Several of our products help our clients minimize their time spent during their typical KEC cleanings. Our partnership with Teinnova directly corresponds to our goal.

The Tegras concept helps our clients minimize their time spent at each KEC cleaning, is easy to use, protects their team, and saves them money. The Tegras methodology can reach all spots needing to be cleaned that are typically inaccessible by other methods. The Tegras system was engineered to provide a definitive solution to the problem of cleaning kitchen extraction systems, hoods, ducts, and extractor fans. With the Tegras system, our clients can significantly improve the efficiency of their cleaning process.

What is the Tegras concept?

The Active Foam

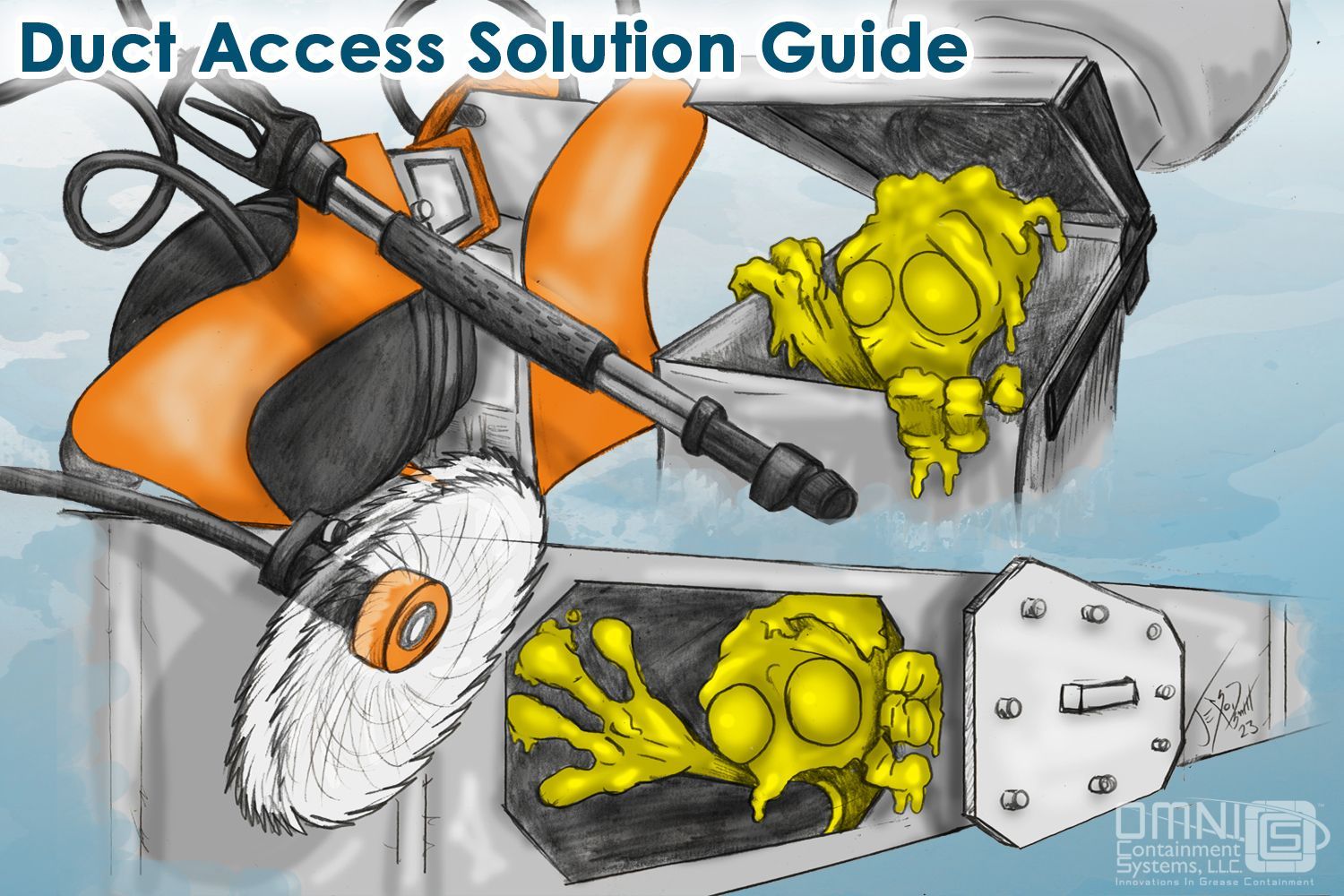

In its simplest description, the Tegras concept is based around the chemical, Comegras. But don’t be fooled; the Tegras chemical is no ordinary chemical. It has been described as “hands down the most effective chemical that I have witnessed.” The foam the chemical makes is effective on every kind of grease; from burgers to Asian restaurants to bistros, there’s nothing that the Comegras can’t destroy.

The chemical, Comegras, is inserted into the ifoam pro or the ifoam mini. This features two active foam generators that apply the highly effective foam to the affected area. The foam adheres to the grease and immediately begins to break it down. The foam is dense, helping it cling to the grease and dissolve it from the ductwork surfaces. The heaviness of the foam and grease concoction helps to pull everything down with gravity.

The Mechanical Action of the Brush

You may be curious how the foam is spread throughout the ductwork; that’s where the brush comes in. Tegras designed duct-brushing robots. There are two versions of this pneumatic brush: The forte and the multipro. Each power through the ductwork, applying the foam and scrubbing with pneumatic brushes. The brushes can cause fractures in thick, caked-on grease buildup. This allows the foam to penetrate the grease and break it down from within.

The brushes are designed to accomplish two things:

- Break apart the grease to deliver the foam into and behind the grease

- Polish the surface after the foam has broken up the grease

Once the foam and grease combination begin to slide down (as mentioned above) it’s time to perform the final cleaning with the brushes. The brushes can now be used to scrub off any remnants of grease deposits, leaving a bare-metal clean.

The Required Source of Compressed Air

The AR-18 Air Compressor is the power behind the foam and brush system. Given that the Tegras brushing machines are both pneumatic, an air compressor is necessary—but not just any air compressor. Enter the AR-18. The AR-18 can produce enough torque to spin the brushes through the toughest, densest grease build up. It produces 9.2 CFM using only 110v power; this kind of air output is nearly unheard of in the realm of 110v air compressors.

The second-best part of the Tegras air compressor is that it can be setup with dual connections, meaning you can run a brushing machine (either the multipro or forte) at the same time as the ifoam mini, making setup time a breeze.

Conclusion

The Tegras concept is designed to save time by automating the kitchen exhaust cleaning process. With the brushes available, there is enough line (90 feet) to run through long lengths of ductwork—no need to setup multiple access points. The foam goes on thick, typically eliminating the need for multiple applications (again, saving more time!). With the ifoam pro, it’s easy to switch from foamer to pressure washing unit at the touch of a button (plus, you have the option to get a remote, too). The Tegras concept will save you time and money, allowing you to give each kitchen its best clean. Contact Omni Containment today to discuss or purchase this revolutionary product.

Share This Blog Post!