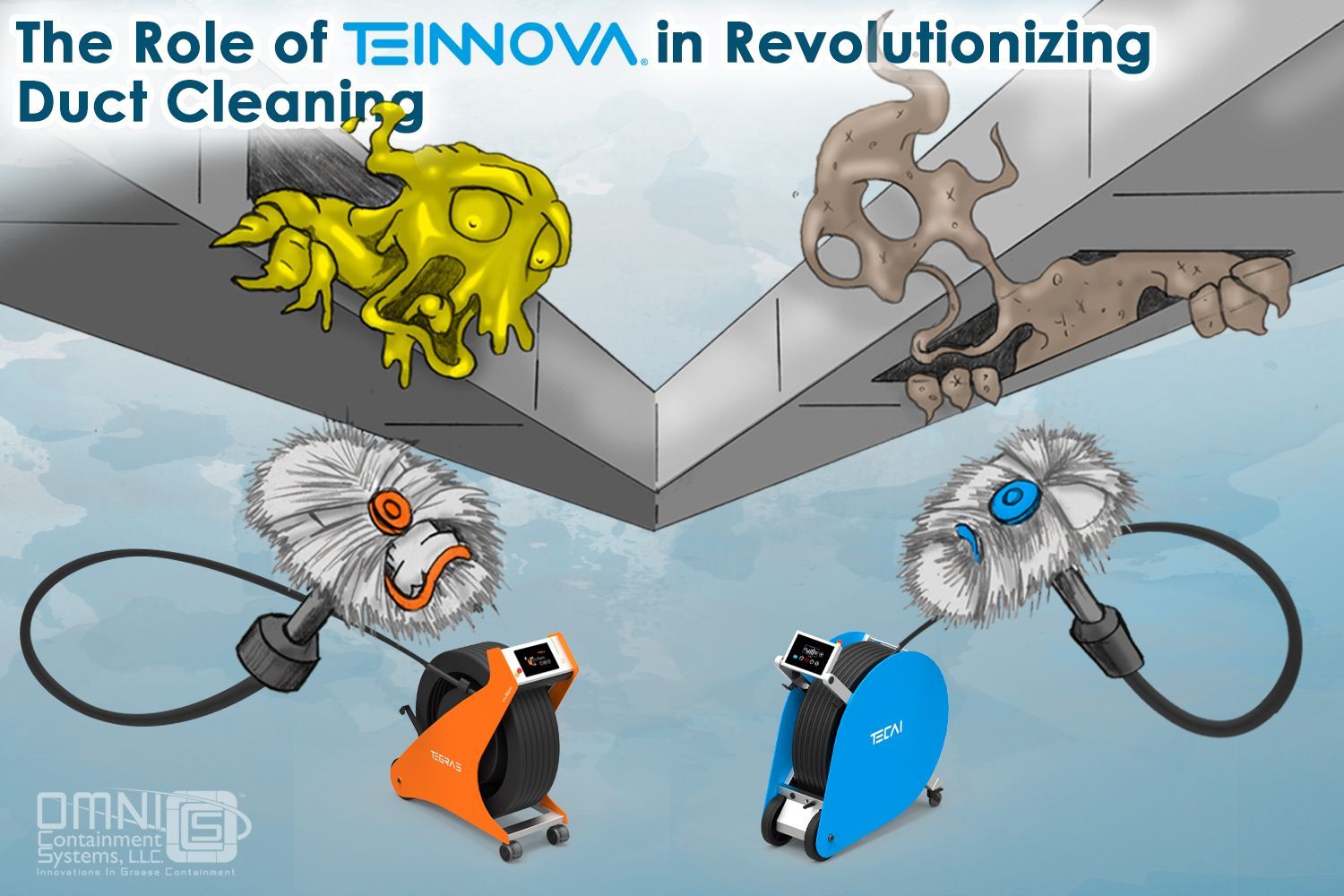

The Tegras Advantage

The Tegras advantage saves our clients time and money. Kitchen exhaust cleanings are easier, the equipment protects their team, and it’s portable. The entire Tegras concept was engineered to provide a definitive solution to the kitchen exhaust cleaning community. With the Tegras system , our clients can significantly improve the efficiency of their cleaning process. We’ve spent most of the year discussing the Tegras advantage and created a recap of the highlights.

What is the Tegras concept?

The Active Foam

The chemical, Comegras, is inserted into the iFoam pro or the iFoam mini. The foam adheres to the grease and immediately begins to break it down. The foam is dense, helping it cling to the grease and dissolve it from the ductwork surfaces. The heaviness of the foam and grease concoction helps to pull everything down with gravity.

The Mechanical Action of the Brush

The brushes are designed to accomplish two things:

- Break apart the grease to deliver the foam into and behind the grease

- Polish the surface after the foam has broken up the grease

The Required Source of Compressed Air

The AR-18 Air Compressor can produce enough torque to spin the brushes through the toughest, densest grease build up. It produces 9.2 CFM using only 110v power; this kind of air output is nearly unheard of in the realm of 110v air compressors.

Minimize Scrapers

Fewer Access Points

When performing a typical scraper duct cleaning, access points must be installed every twelve feet. If it takes roughly fifteen minutes to open just one access point, not including cleaning and closing that access point, there is a huge time savings here when using the Tegras Concept. Tegras speeds up the process because there is no need to open every single access point. This results in fewer ladder moves, fewer ceiling tiles to open, and less time wasted.

Save Time, Save Money

The Tegras Multipro can reach ninety-eight feet and the Tegras Forte can reach eighty-two feet of duct. Let’s break down the time savings for the Forte since it can reach a shorter distance (meaning there would be a higher time savings with the Multipro in some instances). For example, you have a duct that is eighty-two feet (the length of the Forte hose). Based on NFPA 96 Standards , this duct length would require seven openings. If you spend a minimum of fifteen minutes at each opening for cleaning, you would save an hour and forty-five minutes just at that one duct.

The Benefits of Automated Cleaning

The Tegras concept speeds up the entire kitchen exhaust cleaning process, almost to the point where it could be considered automated cleaning. The combination of active foam, mechanical brush, and compressed air speeds up the entire kitchen exhaust cleaning process while making it easier. Additional benefits include:

- Heavy duty, thick foam; clings to grease; safe to work with

- No need to change tools between use; eliminates need for multiple pieces of equipment

- Adjustable lance; adjusts between 20 and 140 degrees

- Less time spent; more money earned; more time for new clients

- Small; portable; relatively light weight (180 lbs or less)

Conclusion

The Tegras advantage starts with the chemical, Comegras. It’s thick, effective, and safe to use. The brushes are designed to break apart grease and polish surfaces clean. The Tegras advantage allows you to save time, and therefore earn more money and have room for more clients. The system turns your work from manual labor into mostly automated labor. Adding this concept to your arsenal will give you an advantage in the industry. Contact an Omni Containment Systems representative to discuss purchasing your Tegras system today.

Share This Blog Post!

The Role of TEINNOVA in Revolutionizing Duct Cleaning: A Collaboration with Omni Containment Systems