Evolution of Restaurant Rooftop Grease Containment at Omni: The Grease Gutter

There have been restaurants in the United States since America became a country in 1776 and even before. The Griswold Tavern in Newport, Rhode Island may have been the first restaurant to open after the US declared its independence from England. Since then, the number and variety of restaurants has grown and grown to the point that in 2016 there were a total of over 620,000 dining establishments in this country! That’s a lot of food, a lot of cooking, and a lot of grease! Restaurant operation requires much more than acquiring and feeding customers. That list of requirements is longer than a giraffe’s neck, so we will narrow the focus to rooftop grease containment and Omni’s role in the evolution of products to achieve that end: starting with the Grease Gutter.

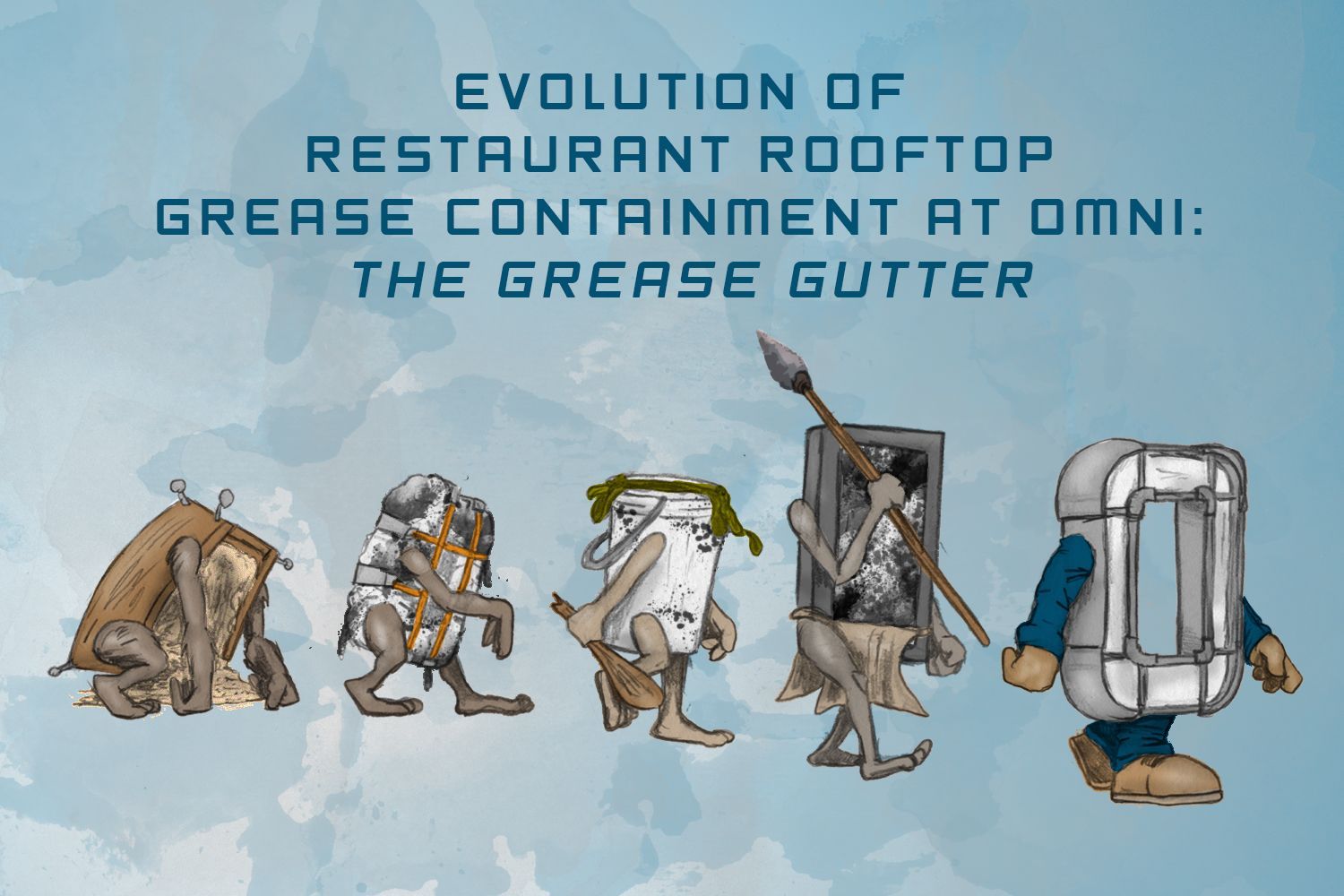

The hood and duct cleaning industry has evolved from being non-existent to playing a vital role in the safety of restaurants, people, and the surrounding environment. Part of that job entails the cleaning of the rooftop exhaust fan and keeping the roof area around the fan free of grease. A couple of very primitive early solutions included placing a bucket or some other receptacle beneath the grease drain spout or building a frame box around the fan and filling it with sand or porous rocks to absorb the grease. Those ideas had major flaws. A bucket would overflow with grease or substantial rainfall over time. If it wasn’t tended to on an almost daily basis, the roof would end up a greasy mess. Sand and rocks absorbed grease but also needed constant attention. And what a backbreaking chore removing the grease saturated sand and replacing it was!

New, more effective ideas to solve this problem were needed. Kevin Chwala, Omni Containment Systems founder, had spent years and years in the hood and duct cleaning industry. He had the experience, an inventive mind, and the business acumen to solve the problem. Kevin came up with a few early solutions, fine-tuned them, and eventually hit upon a breakthrough answer that he called the Grease Gutter. The Grease Gutter is a simple, yet very effective method of capturing grease and preventing it from reaching the roof. The name pretty much describes it. It is a durable polypropylene gutter that is installed around the rooftop fan. A filter, or absorbent media, is placed in the Grease Gutter and is exchanged as it becomes saturated. The reason this system lasts much longer than a bucket is because the filters absorb grease, but they don’t absorb water! Water runs right through the filters and is funneled onto the roof through drainage channels at the bottom of the gutter. This prevents the filters from becoming saturated after rainfall.

The Grease Gutter revolutionized the rooftop grease containment aspect of restaurant maintenance and safety. It performed the job better than any product before it, and still does. The Grease Gutter is easy to install and even easier to maintain. This simplicity is a big key. Previous attempts to solve the situation involved difficult and time consuming installations. This is not the case with the Grease Gutter, which takes less than an hour to install. More importantly is the ease of servicing. Remove the saturated filter on a timely basis, dispose of it properly, and insert the replacement filter. Nothing to it and it takes 10 minutes tops! Compare that to the hours it would take to remove and replace heavy sand or lava rocks, or install complicated and unwieldy multi-layer filter systems.

Since the very beginning of the company, Omni has been the leader in creating and developing solutions to the challenge of grease containment. The Grease Gutter and its economical one-sided brother, the Sidekick, were the beginning. Lots more would soon follow, but that’s for another time. You can check out our website here.

Share This Blog Post!

The Role of TEINNOVA in Revolutionizing Duct Cleaning: A Collaboration with Omni Containment Systems