Restaurant Fire Safety: Tips & Prevention for October and Beyond

October’s spooky season is upon us, and while people get engrossed in planning Halloween marathons and assembling costumes, there is a more sinister threat lurking in many restaurants: the danger of fire in kitchen exhaust systems.

According to the National Fire Protection Association (NFPA), a considerable number of restaurant fires start from kitchen cooking appliances that can rapidly spread through the kitchen exhaust system. NFPA’s data from 2010 to 2014 indicates that an estimated 7,410 structure fires occurred annually in eating and drinking establishments. The aftermath? A staggering average of $165 million in direct property damage each year.

Given the cocktail of risk factors present in restaurants, including open flames, hot equipment, electrical connections, cooking oils, cleaning chemicals, and paper products, it’s clear that restaurants have all the ingredients for fires to spiral out of control. Neglected, grease-laden exhaust systems can quickly facilitate fires, escalating damages even before fire departments can respond.

However, it is not all doom and gloom. Restaurant owners can protect their establishments against these devastating commercial kitchen fires. An initiative-taking approach includes prioritizing fire safety and having kitchen exhaust systems regularly cleaned by certified professionals. Let us delve deeper into essential preventative measures in your commercial kitchen:

Kitchen Exhaust Systems

Frequency of Inspection & Cleaning:

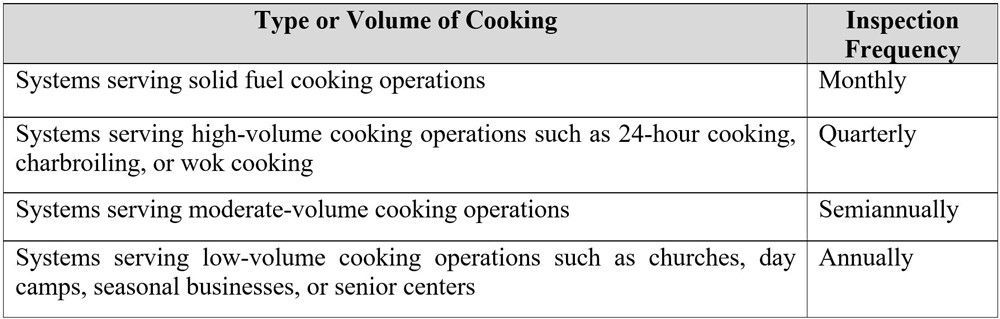

- Having your kitchen exhaust system regularly cleaned by certified professionals is the best way to protect your establishment from the threat of fire. Often, restaurant owners ask, “ How often should my kitchen exhaust system be cleaned or inspected and by who?” The answer depends on the volume of your cooking operations. More cooking translates to increased grease buildup, necessitating more frequent cleanings. The NFPA 96 provides a detailed guideline in this regard.

Refer to the NFPA 96 Table below:

Awareness & Access

- Ensure your kitchen staff and facility managers are aware of grease buildup in exhaust ducts. Installing adequate access doors in your kitchen exhaust system is essential. Per NFPA 96 requires access doors at the sides or at the top of the duct, and at a change of direction, for inspection and thorough cleaning. NFPA 96 specifies an access door opening every twelve feet to allow the KEC personnel to reach all areas of the kitchen exhaust duct systems, so the grease and other contaminants are removed right down to the bare metal.

- Want to check grease buildup yourself? Tools like the Grease Comb can assist, or a professional kitchen exhaust cleaner can do the inspection for you. And always check the sticker on your hood to note the last cleaning date.

Kitchen Exhaust Fans

Cleaning and maintaining exhaust fans are an important part of your kitchen exhaust system maintenance schedule. Kitchen exhaust fans not only need to be regularly cleaned, but there are also several exhaust fan accessories you need. Here are key aspects to remember:

- Grease Containment System – Having the proper grease receptacle for your kitchen exhaust fan is vital to prevent fires, protect the roof membrane, prevent fall hazards, and prevent grease from entering waterways.

- Fan Hinge Kit – The NFPA mandates exhaust fan hinges for upblast fans to enhance safety. This also ensures easy access for maintenance.

- Access Panel – Unbalanced fans cause unnecessary wear and can lead to fan failure. To maintain balance and efficiency, ensure that your fans have access to a cleanout port.

Certified Kitchen Exhaust Cleaners

A complete cleaning covers every inch of an exhaust system and leaves nothing behind but bare metal. The NFPA 96 standards underline that kitchen exhaust cleaning is instrumental in reducing fire risks. Always opt for certified kitchen exhaust cleaners who provide comprehensive inspection reports and compliance certificates. If you are searching for a trusted kitchen exhaust cleaner, reach out, and we can connect you with our extensive network.

In conclusion, with vigilant fire prevention measures, the terrifying risks associated with kitchen exhaust systems can be effectively mitigated. By fostering a fire safety culture, we protect more than just infrastructure; we safeguard invaluable human lives. If you are curious about Omni Containment System’s fire prevention offerings, please get in touch. We are here to guide and educate you on our range of products and equipment.

Share This Blog Post!