Grease Containment Solutions

Omni Containment Systems leads the industry with innovative solutions for managing fats, oils, and grease containment. Our comprehensive product line is designed to be both cost-effective and environmentally responsible, ensuring your business meets its containment needs efficiently.

We offer a wide range of products, including access doors, hinges, grease containment systems, replacement filters, and various accessories. Our commitment to innovation and excellence has established us as a trusted leader in grease containment solutions.

Discover the Omni Containment Systems difference and elevate your containment strategy with our advanced, reliable products.

Grease Containment

View Products

View ProductsEffective rooftop grease containment is essential for preventing rooftop damage and ensuring safety. Standard grease catches on factory upblast or industrial set fans often do not meet these critical needs. Omni Containment Systems offers unparalleled expertise in this field, with five distinct patented rooftop grease containment systems. Additionally, Omni Containment Systems provides a unique patented pavement protection system to safeguard grease corrals and drive-thru lanes.

Each system is specifically designed to accommodate various exhaust fan configurations, providing an accessible and cost-effective solution for all grease containment requirements. Our innovative hydrophobic filter technology assists with EPA wastewater compliance and helps mitigate wastewater pollution. Additionally, Omni Containment Systems is committed to sustainability, manufacturing our products using recycled materials.

Replacement Filters

View Products

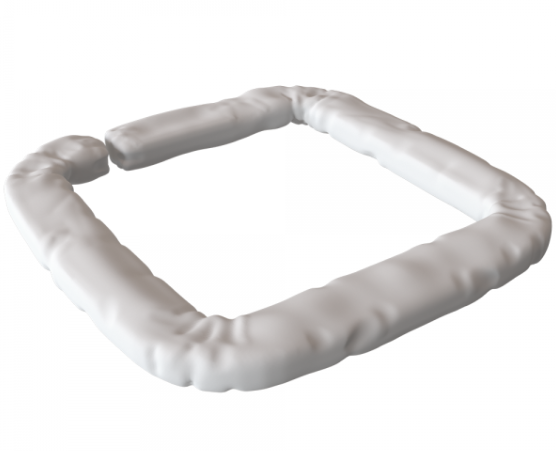

View ProductsOmni Containment Systems replacement absorbents are designed to prevent rooftop grease discharge damage. Each Omni Sorbent product is hydrophobic, absorbing only fat-based oils (not precipitation), and features a proprietary additive that neutralizes grease. The Fill-More Grease Boom™ and Fill-More Grease Pillows™ come with a durable, flame and UV-resistant outer skin, filled with recycled filter materials. The Roof Guardian™ line of filter pads are made from UL-listed materials and can contain up to five times their weight in ventilator grease discharge.

Fan Hinging Solutions

View Products

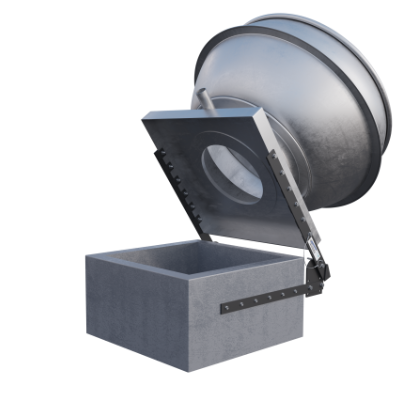

View ProductsThe National Fire Protection Association (NFPA) mandates exhaust fan hinges for upblast fans to enhance safety and ensure easy access for maintenance. While standard hinges are included with all kitchen exhaust upblast fans, they do not comply with NFPA Fire Code 96. Installing a compliant hinge kit ensures your system is easily accessible for cleaning and safe to work on.

Omni Containment Systems offers three main styles of our Super Hinge™ in a variety of sizes. The Super Hinge™ revolutionizes the process of hinging exhaust fans for cleaning and maintenance. With patented technology, it provides exceptional ease, convenience, versatility, and durability. Additionally, it extends the lifespan of expensive fan housings by providing added support to vulnerable areas of the fan base.

Access Door Solutions

View Products

View ProductsAccessing your HVAC and restaurant kitchen exhaust ducts has never been easier. Access Armor™ Duct Access Doors are designed to overcome the flaws of conventional access panels with their patented “Cam-Lock” design, which eliminates the risk of misplacing fastening hardware. Exceeding NFPA 96 and UL specifications, Access Armor™ offers an impressive 2300-degree fire rating for superior safety and reliability.

Product Accessories

View Products

View ProductsOmni offers additional products designed with the typical kitchen exhaust cleaner in mind. Check out how our accessories can make your job easier and more efficient!

Upgrade your grease containment with Omni products.